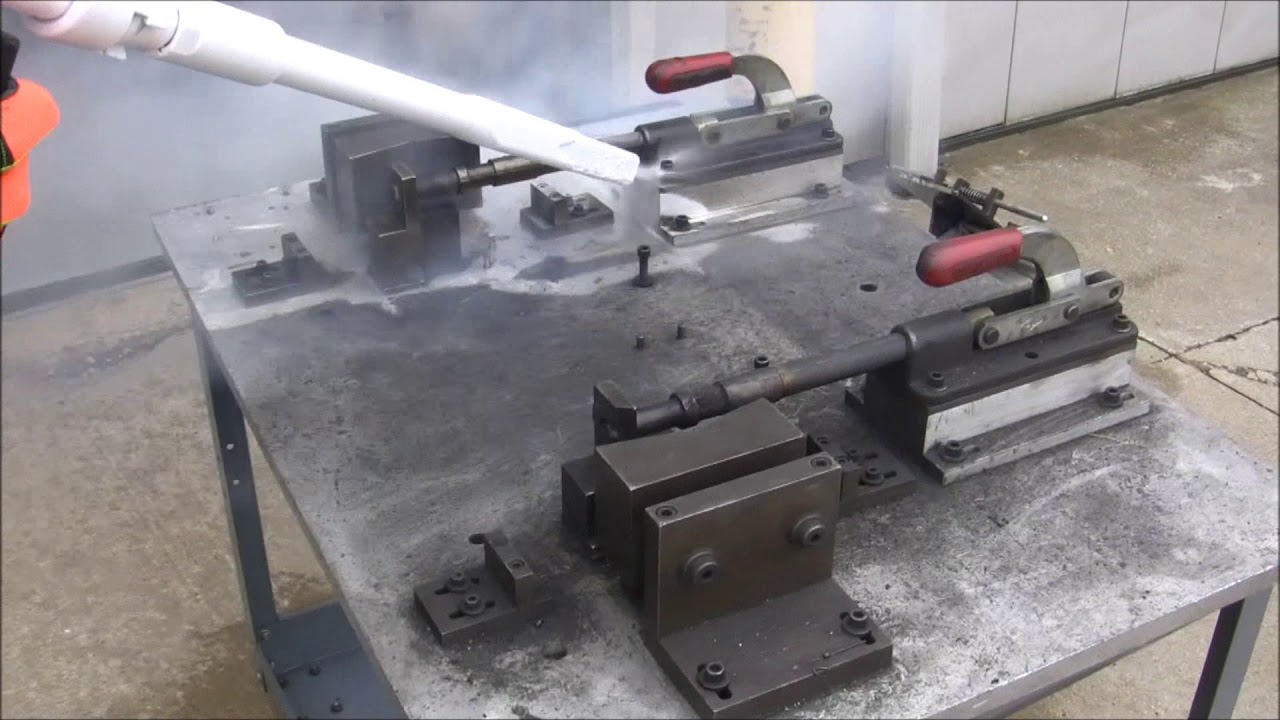

HOW DOES DRY ICE BLASTING WORK?

Dry ice blasters blast carbon dioxide pellets or MicroParticles at supersonic speeds using compressed air. These pellets/particles then sublimate on impact and lift dirt and contaminants off the underlying substrate. Dry Ice Cleaning

What Is Dry Ice Blasting Used For?

Dry ice blasting is a non-destructive solution for cleaning, surface preparation, and parts finishing. Dry ice blasting does not require water or cleaning chemicals and does not produce secondary waste. Dry ice blasting (cleaning) can be used in industries like aerospace & aviation, automotive, contract cleaning, food & beverage, plastics & composites, restoration, textiles, and more. Common applications within these industries include adhesive removal, coatings & corrosion removal, composite tool cleaning, remediation, parts finishing, and surface preparation. As you can see, dry ice blasting can be used for a wide range of applications.

What Are The Key Benefits Of Ice Blasting?

- Reduce downtime Significantly quicker process leads to increased production time.

- Increase efficiency Clean equipment online, while eliminating need for cooldown and disassembly.

- No secondary waste Dry ice blasting does not produce secondary waste streams, residue or moisture.

- Non-abrasive Dry ice is a soft media that will not harm substrates.

- Improved part quality and reduced scrap Cleaner machinery and tooling results in higher quality products.

- Environmentally sustainable Dry ice is made of recycled CO2 and does not add additional CO2 to the atmosphere. It also significantly reduces water use for sanitation.

- Operator safe Eliminates need for chemicals and repetitive, manual processes.

- Non-toxic and non-conductive Dry ice is a food grade media and is safe for commercial use.

- More efficiently allocate labor The process reduces time, labor and resources needed.